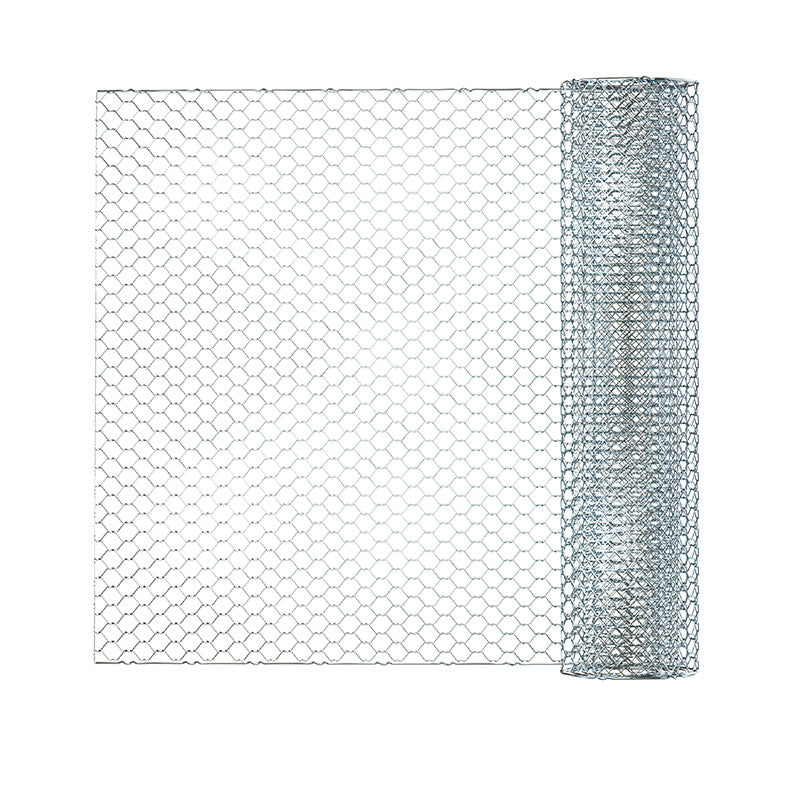

3/4 Inch Wire Mesh

FREE SHIPPING

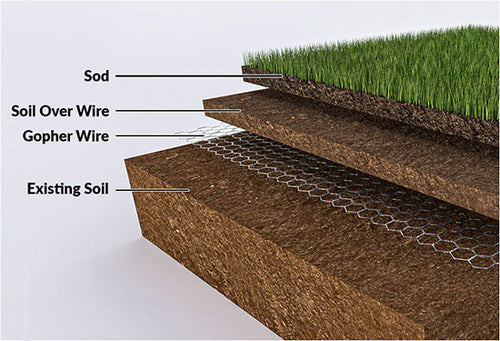

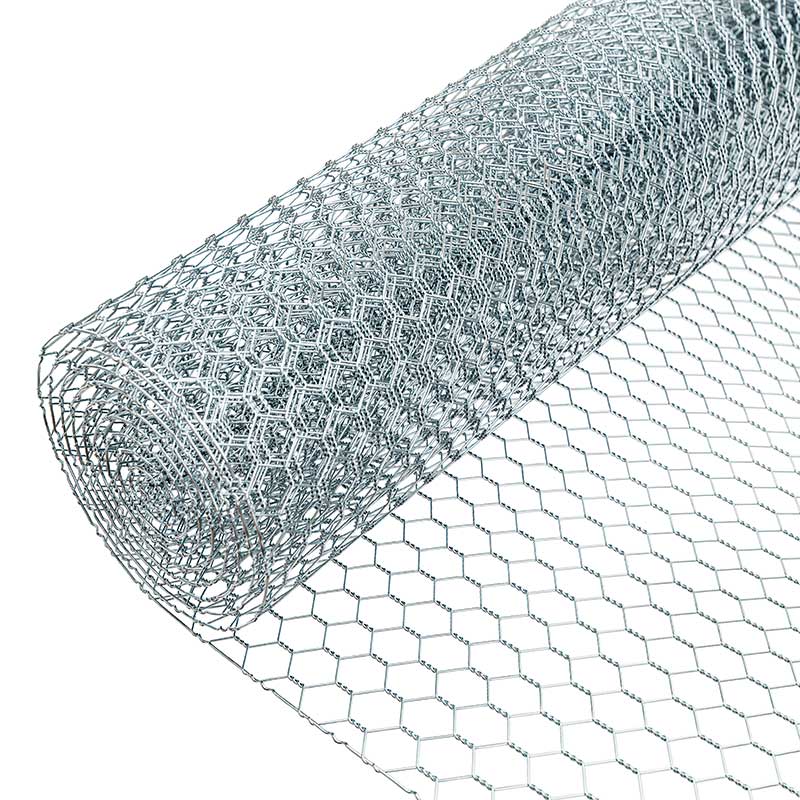

Our 3/4 Inch Wire Mesh is a commercial grade wire that is made from either galvanized or stainless steel. This product can be used in multiple applications where a strong, yet flexible woven wire is needed. This product provides high levels of rot and corrosion resistance in both above and below ground applications.

The galvanized option is galvanized before and after weaving and has an estimated lifespan of 6-10 years. The stainless steel option has an estimated lifespan of 25+ years and is constructed of T-304 / 18-8 stainless steel.

The 3/4 inch wire mesh is 20 gauge, available in a 100' roll length, and ships from Northern CA.